Professional Services

Makhenikha Engineers has in place a Quality Management System that complies with the requirements of ISO 9001:2015(E). The company’s Quality Policy is available on request as well as the Quality Manual. The company is working towards attaining the ISO 9001:2015(E) certification.

Mechanical design and Product development

Makhenikha Engineers offers advanced mechanical engineering design and product development services to customers across multiple industries assisting them in developing their ideas to products. Our innovative design engineers have comprehensive knowledge and experience and can assist customers with the following mechanical design and product development:

- - Turn-key Mechanical Engineering Product Design

- - Conceptual Development

- - Detailed Design

- - Engineering Calculations

- - Engineering Analysis and Simulation

- - 3D CAD Modelling (Autodesk Inventor)

- - Design Drawings

- - Prototyping

- - Fabrication Drawings

- - Manufacturing support

- - All Designs sign-off by an ECSA Registered Professional

Reverse Engineering (3D scanning)

Makhenikha Engineers uses the latest 3D scanning technologies which can be used on-site to take extensive, accurate measurements of a structure in a short time – reducing downtime and improving safety. This data can then enable us to design wear parts, develop repair strategies and repair parts off-site, as well as support with reverse engineering and documentation of components and structures. The following services are offered:

3D Scanning

- - Collecting data

- - Acquiring accurate physical objects dimension & geometry

As-Built Documentation

- - 3D & 2D As-built drawings

- - Verify plant drawings (As-built) and update

Reverse Engineering

- - Generate 3D solid models from existing components

- - Redesign

- - Generate 2D manufacturing drawings

Non-Destructive Testing (NDT) Services

Makhenikha Engineers provide Non-Destructive Testing (NDT) Services, Structural and Mechanical Inspections. Engineering solutions to a diversified and demanding customer base of leading corporations in the Southern African Region.

Mechanical inspections – Consists of in-service mechanical inspection of bulk material handling equipment and surveillance inspection of repair items and machinery in the heavy engineering industry.

Structural inspections – Consists of fabricated steel (Welding), on site (static & dynamic structures) integrity and root cause analysis of failures in bulk material handling equipment

The methods mentioned below, have unique properties that make specific defect detection possible. We always make sure we use the correct inspection method to achieve the best testing results.

Building services (HVAC, Fire protection, Wet Services and other)

Makhenikha Engineers offer full engineering solutions tailor-made to suit each customer, and these include the entire project life-cycle, starting from project development, scoping, pre-feasibility, and feasibility studies, detailed design, tendering and procurement, contract management, installation supervision, quality management, as well as commissioning and hand-over.

On-going support, maintenance and servicing of the mechanical systems installed. Makhenikha Engineers utilises AutoDesk software products (AutoCAD and Revit MEP) for the design of the building services

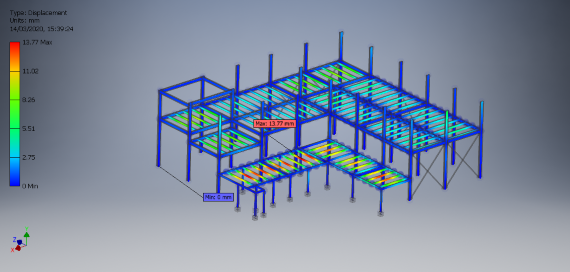

Finite Element Analysis

Makhenikha Engineers provides a wide range of Finite Element Analysis consulting services to a variety of industries. Our FEA engineers are highly experienced with exceptional analytical skills and technical knowledge and by utilising NASTRAN in-CAD, can assist customers with the following advanced Finite Element Analysis services:

- - Linear Static Analysis

- - Non-linear Analysis

- - Thermal Analysis (Transient and Steady State)

- - Fatigue Analysis

- - Buckling Analysis

- - Design Optimization

- - Design Verifications

Industrial Electrical Supply and Repairs

Makhenikha Engineers Industrial electrical supply and repairs involve providing and maintaining electrical components and systems used in industrial settings. This includes the supply of parts like transformers, circuit breakers, motors, wiring, and other electrical equipment, as well as services such as installation, troubleshooting, maintenance, and repair of these components.:

- - Pumps

- - Motors

- - Electronics

- - Electrical

- - Lubricants